Dust-free Work Shop

Strictly follow the standard process to establish and control the temperature, cleanliness, indoor pressure, airflow velocity and distribution, noise, vibration, lighting, and static electricity in a dust-free room within the required range.

Dust Free Manufacturing Standards

High standard clean environment facilities built according to standards, regularly monitoring and testing air quality, equipment, temperature and humidity, etc.

Temperature And Humidity Control

The temperature in the workshop is usually controlled between 20-25 degrees Celsius, and the humidity is controlled between 45% -65% to ensure the stability and quality of the product.

Air Flow Control

Unidirectional air flow, with clean areas flowing towards non clean areas to prevent pollutants from entering the clean area.

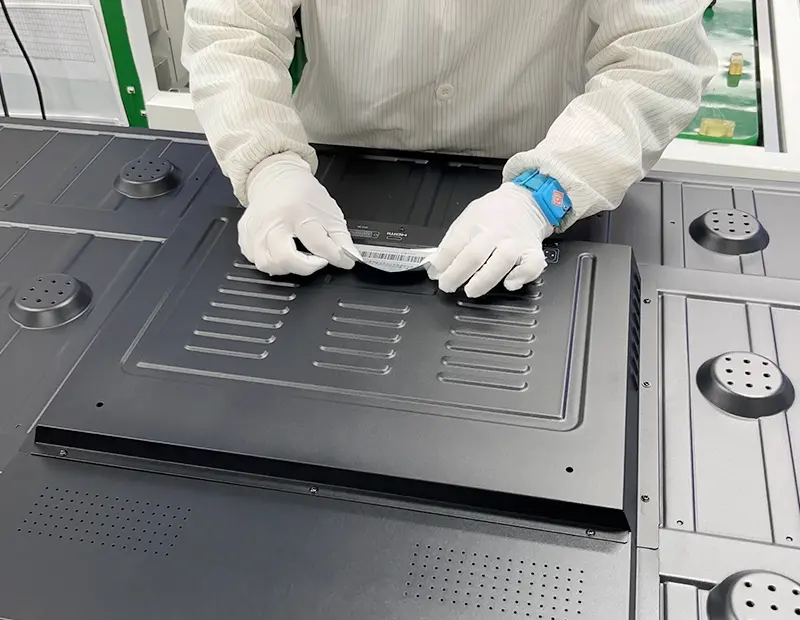

Electrostatic Control

Wall and floor materials are dust-free, corrosion-resistant, high-temperature resistant, and less prone to generating static electricity.

Wearing electrostatic gloves during the production process can also prevent fingerprints from being left behind.

Air Cleanliness

The air cleanliness requirement is to meet ISO level 6 (or equivalent to Class 1000 of the US Federal Standard 209E), which means that there should be no more than 1000 particles per cubic meter of air and no more than 350 particles with a diameter greater than 0.5 microns.

Workshop Management

Ensure the smooth progress of production activities, improve production efficiency, ensure product quality, reduce production costs, and ensure the safety and health of employees.

Production Process

Job skills training, strictly following the execution standards, processes, and production drawings for production.

Safe Production

Regularly rectify and eliminate safety hazards, wear protective equipment according to regulations, and strictly implement various safety operation regulations.

Equipment Management

Establish a management system for equipment use, maintenance, and upkeep.

Personnel Behavior Control

The staff shall wear protective equipment, such as clean clothes, clean shoes and clean hats, and carry out full body disinfection and sterilization before entering the workshop, otherwise it is prohibited to enter.

Data Analysis

Perform statistical analysis on production data, optimize production processes, and improve production efficiency.

Environmental Management

Keep the workshop clean and orderly, and implement 5S management (organization, rectification, cleaning, and literacy).